What are the Differences Between NHXMH and NYM

What are the Differences Between NHXMH and NYM? Cables and wires are the most frequently used materials in the field of communication and electricity. The fact that a single cable is a group of conductors is considered to be the most important difference between wires and cables. Conductors are produced from common materials such as copper or aluminum. Some of the wires, which are mostly bare and bendable, are covered with a thin PVC layer. Cables that run parallel to each other must be bent or connected together to form a single casing. At the same time, it has inner and outer covers in order to provide the necessary safety standards.

Wires can be used for carrying electrical and mechanical loads, heating any industrially produced part, and transmitting telecommunication signals. Cables, on the other hand, are products that are frequently used in power transmission, carrying electrical and telecommunication signals.

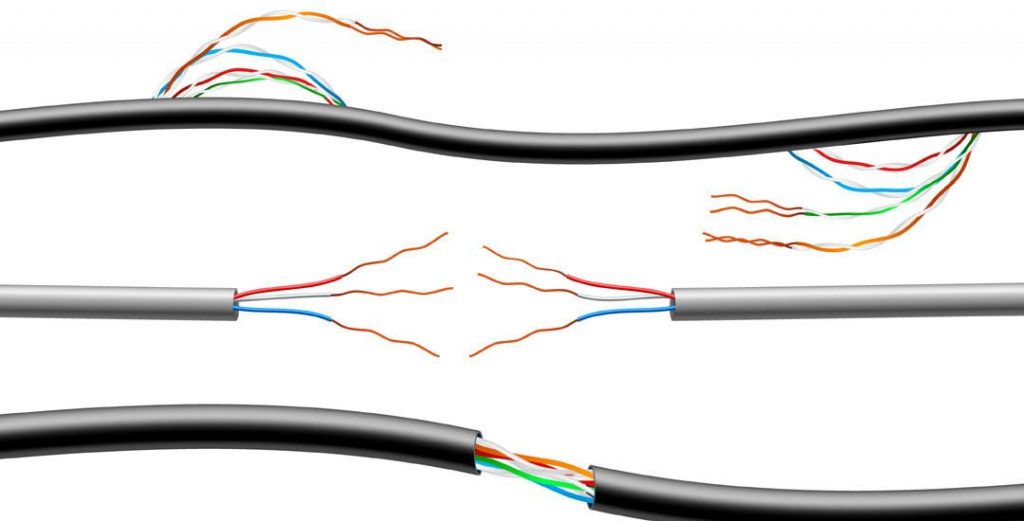

In order to obtain the best performance, the wires and cables should be selected in accordance with the usage area and purpose. It is very important to replace damaged or torn wires and cables. In addition, the polarization of all cables and wires used and the safe installation are among the issues to be considered.

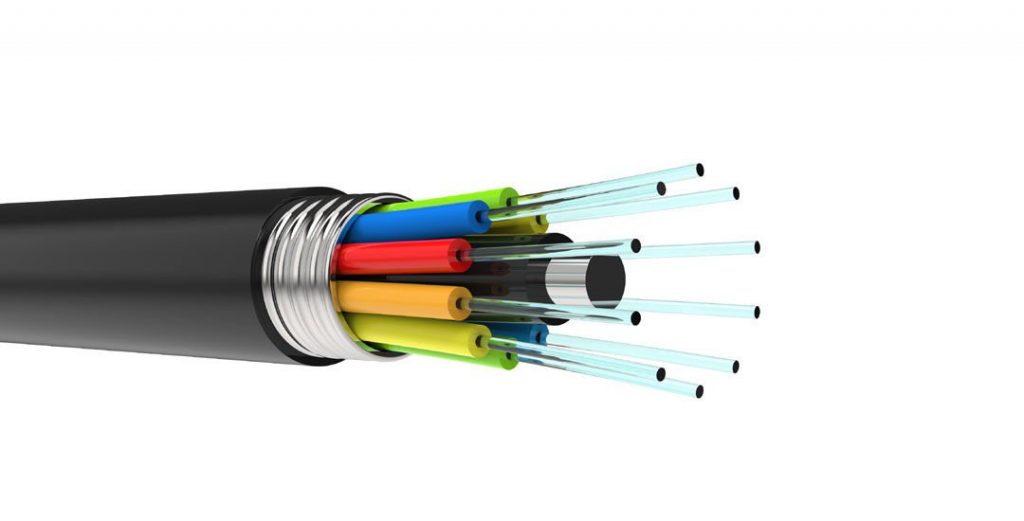

Multi-core, special synthetic insulated, special synthetic outer sheath, fine stranded copper conductor, special filler layer, flame retardant, halogen-free energy cables are called NHXMH cables. NHXNH cables are produced in accordance with TSE K 328 and the allowable operating temperature is 90 degrees and the maximum short circuit temperature is 250 degrees. NHXMH cables are halogen-free, with core insulation of cross-linked polyethylene compound, core color black for single core cable, twisted in layers with optimal laying length for multi-core cable. Its structural properties can be expressed as solid or stranded copper conductor, HFFR filler, HFFR outer sheath and XLPE insulation.

NHXMH cables do not transmit the flame during a fire and do not cause a dense layer of smoke. Therefore, they do not lead to a corrosive environment. Thus, the safety of life and property is ensured at a high level. NHXMH cables, which can be mounted on or under plaster, can also be used in brick and concrete, except for direct burial in vibrating or compacted concrete.

The use of NHXMH cables is especially advantageous in buildings or industrial facilities where many people and goods are cold. Since they do not form halogen and corrosive gases under the influence of fire, smoke formation is minimal and the damage they cause is much less than cables that do not have this feature. NHXMH power cables are used quite frequently in institutions where low smoke and corrosive gas emission and fire protection features are needed.

Due to their structural features, NHXMH cables are one of the most widely used cable types in hotels, shopping malls, hospitals, power plants, data processing centers, public transportation by rail systems, and fire-hazardous facilities where many valuable devices and people are located. Although they are designed for installation in dry, damp and wet places, as well as on bricks or outside the wall surface when the necessary protection is provided, they are not intended to be used directly on the soil.

What Does NYM Cables Do?

NYM cables with one or more strands and copper conductor can be used in high voltage, humid and humid areas. NYM cables, which are cables with one or more PVC-based special thermoplastic insulation, can also be called multi-core antigron cables.

NYM cables are extremely safe cable types that can be used in line drawings from electrical panels, as well as in environments where there are dangers such as explosion, fire or explosion, thanks to their durable structure.

NYM cables have special communication conductors that are needed during the installation of power supply networks and lighting systems, when working on electricity supply or distribution in fixed units.

NYM cables are used extensively in warehouses, businesses and workplaces where it is possible to encounter serious risks such as explosion, fire and similar. If applied with the right methods, NYM cables can also be used in wet, humid and dry interior spaces. If they are not exposed to direct sunlight, it is preferable to use NYM cables outdoors.

In addition to all these, NYM cables can be used in application areas where mechanical stress is not in question, in plastered and non-plastered applications of all kinds of structures. It should be noted that NYM cables are not suitable for underground use, as there is a risk of rodent damage under the ground. For this reason, care should be taken not to lay NYM cables underground, although they are used in residential and industrial areas that do not require mechanical protection.

NYM cable types, which can be used very comfortably in places with high voltage danger, have an extremely durable structure, so they are a type of cable suitable for use in almost all areas, except for laying under the ground.